If you’ve been following me on Facebook or Instagram then you already know that we have been tackling a makeover on our kitchen stairwell. I originally intended to just make one big stair makeover reveal post, but then I realized that it would be a ridiculously long post and pretty boring for those of you who just want to see the pretty “after” pictures. So, instead I decided that this post would be about the more technical aspects of building new wood stair treads and finishing them. Look for the whole stair makeover reveal later this week.

If you are just joining us this is what we started with:

I had hoped that when we ripped up the carpet that we would find nice wood stair treads that we could refinish underneath, but like many 1980’s era track homes we found particle board instead. I was pretty bummed, but Cody was actually relieved. He had already decided that building new treads would actually be less work than trying to revive old ones full of staples and nails.

Now, you can buy pine stair treads at Home Depot for about $10.64 a piece. These treads are basically a pine board that has been routed to be round on the front of the tread. We needed 10 treads, so that would have brought us to $106.40. That’s not terrible, but there were a couple of issues with these treads. 1) they are only 1 in think which we decided would look pretty puny once installed and 2) ours stairs have exposed sides which means we still would have had to route some of the boards.

I found these nice chunky 2 in stairs treads, but at $123.75 a piece for “paint-grade” ($1237.50 total!) they totally blew the budget. So, we decided to just make our own stair treads.

Building stair treads

The treads are built from 2″x12″ pine boards that were 12′ long. Look for boards with the least amount of knots and that are not warped.

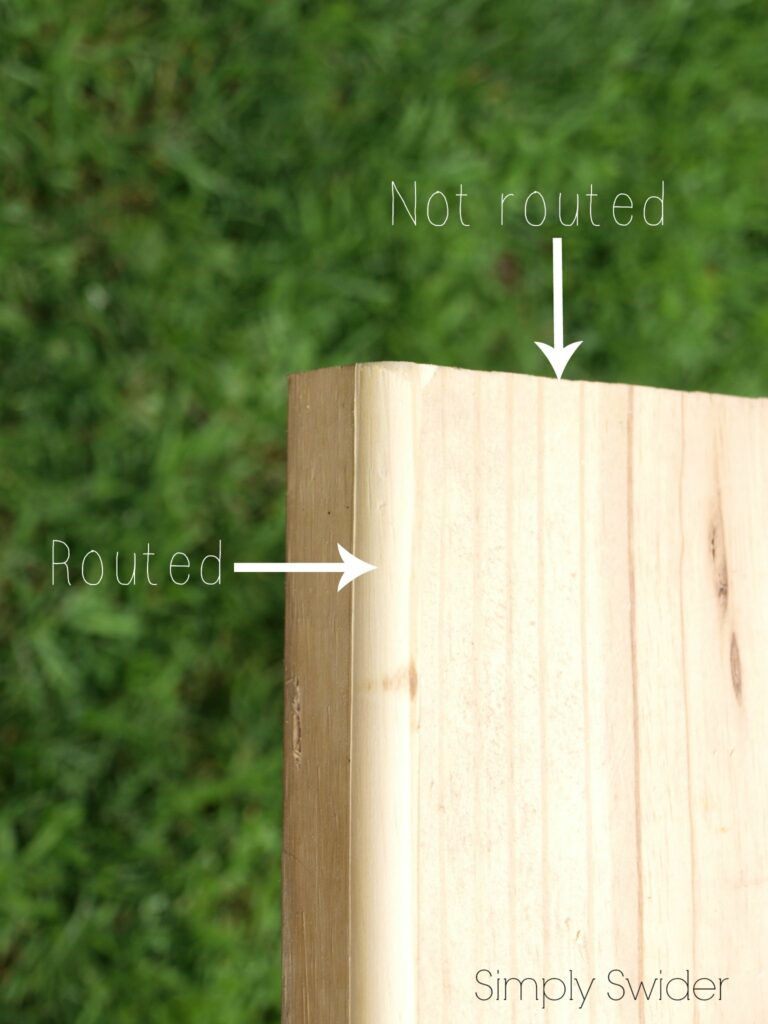

Cody started by securing a 12′ board to a table and routing the front of each board with roundover bit.

Here’s an idea of what it will look like when it’s done. Don’t worry about any imperfections now. Those will be sanded out later. If any of your steps are open on the side (like our bottom 5) you will also have to route the side of those steps.

Once the routing was complete, Cody used a table saw to cut 1″ off the back of each board to make the steps the depth that we wanted.

Finally, he measured and cut each board to the appropriate tread length using a chop saw.

Cody measured and cut each step individually as there were some slight variations is lengths. We dry fitted the steps as we went to make sure everything fit perfect. The bottom 5 steps also required some fancy cuts to account for the newel post, exposed sides, and hand rails.

Finally, we sanded the crap of of each tread with an electric sander to get the boards as smooth as possible.

Staining and Installing

We are finally at my favorite part: staining the treads! I knew from the beginning that I wanted to stain them Mission Oak. It’s my favorite stain color and the same color we used on our industrial console table. Cody didn’t want to take any chances with the color though so I tested out a few options we had lying around on a leftover piece of pine.

Our goal was to match the laminate floors in the kitchen as much as possible. The dark walnut (same as we used on the kitchen counters) and the Jacobean were both a little too dark and didn’t have enough of a honey tone as I would have liked. We decided that mission oak was the winner, but we didn’t want the kind with the polyurethane in it (which is what I had on hand), so off to the store I went only to find out that Mission Oak is only sold as a Polyshades. Sigh….. So, I scoured the shelves for a color that was the most similar to Mission Oak and settled on Special Walnut. I tested it on the pine and we were sold!

Before I started staining the treads I removed any dust with cheesecloth then applied a coat of wood conditioner. Wood conditioner allows the stain to penetrate the wood more evenly. I always use it when staining a highly visible area such as a table top or in this case stair treads.

I allowed the wood conditioner to dry to the touch then using an old rag applied the first coat of stain making sure to go in the direction of the grain. I set up a staining station in the dining room because it was too humid in the garage to get the stain to dry properly.

I applied two coats of stain over the course of one day than allowed the treads to dry overnight before applying the sealer. Finally the treads got two coats of Pro finisher Polyurethane for Floors. I choose a satin finish to keep the treads looking a little rustic like our floors, plus they are easier to keep clean. I sanded between coats then let them dry overnight before installing the treads.

To install the treads Cody started by applying liquid nails to the stair braces (just made up that term). We did this to reduce noticeable nails on the treads and to keep the steps from wiggling.

Next, Cody shot in about four finishing nails on the sides of the treads. This helps them stay in place as the glue dries. We opted not to fill in the nail holds as they were hardly noticeable and added a little more rustic glamor to the steps.

And with that we had working steps again! Building our own steps cost about $100. The same as the off the shelf Home Depot treads except ours our 1 3/4 in thick (that’s $1100 less than the 2 in treads we found online!)

Update: The stairs are done! Check out the complete reveal here!

Update 2017: We used the same treads for our foyer stairs. Check out the whole makeover here!

Has anyone else tackled a stairway makeover? Do you prefer wood or carpet stairs?

Where did you find 2×12 pine?

Hi,

I believe it was Home Depot, but I’m not certain.

Jason.