The goal: High end custom butcher block countertops

The day that was nearly 1 month in the making is finally here: the countertops are done! I won’t even get started on how frustrating cooking is with no counters. I’m so excited they are finally done that I just want to bask in their beautifulness for a while. OK, enough basking. We choose butcher block counters for this kitchen basically because they are budget-friendly. We love the look of them too, but in a budget-free world, I would have gone with a quartz and butcher block combination (which may still happen in a couple of years). We had installed Ikea Numerar Countertops in our last kitchen and not only did we love them but they’ve held up great for the last 5 years. Last time we simply cut the butcher block to length and installed them on top of the counters. Easy peasy. This time around though we wanted a custom, high-end look which was a little, OK a lot, more work, but totally worth the extra effort. I apologize in advance for the length of this post, but there is a lot involved in getting the counters to be this beautiful. I’ll try to break it down into manageable bites for you.

Step 1: Prepping the wood

In order to get the wood to accept the stain, you’ll need to prep it by sanding down all the sides. This is to remove the factory finish.

Step 2: Routing Butcher block

This is actually a surprisingly easy step and makes a world of difference to the quality of your countertops look. In fact, it’s the most commented-on aspect of our countertops. People are always shocked that we were able to achieve these edges on our own.

All you need to accomplish this step is a router and a routing bit. We opted for the French Baroque bit which we bought off Ebay for $23. I suggest you practice on a couple of cutoffs before starting on your actual counters but really this step is almost completely fool proof. There is actually a ball bearing on the router which will insure that you stay at the same depth the entire way.

Look how much more high-end the counters look after being routed! The only other thing you really need to know about this step is that routing wood makes a huge mess. Makes sure to do this outside or in a garage.

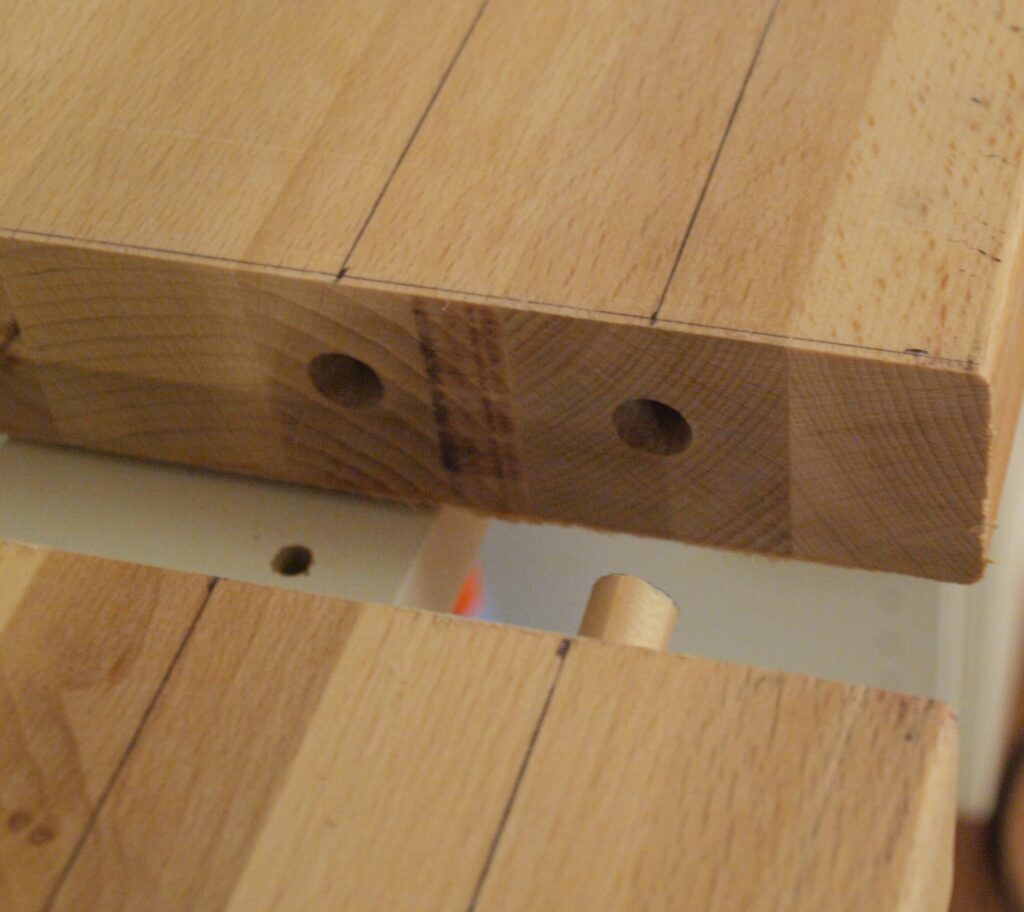

Step 3: Connecting butcher block pieces

We had to use two piece of block on our long wall. Ikea didn’t have a slab long enough to fit our longest wall and in lieu of ease, we opted to join two of the pieces to save some coin.

I used 3/8 wooden dowels and heavy duty construction adhesive to hold everything together. First line everything up and drill the 3/8 holes. We did two in front of the sink and 3 behind the sink to accommodate the amount of room the sink void took up. I dried fit all of the pieces to make sure it all fit.

Once everything is plumb, apply adhesive in each hole and lightly tap the wooden dowels back into place.

Line it all back up and slide the two pieces together. At about 1/4 from the gap in the two pieces it became tough to move any further, Cody literally beat the crap out of the counter to close the gap by butting up at 2×4 to the end of the counter and hitting the wood with a hammer until everything was flush.

Once everything was in place, we used a 1/4 turnbuckle to keep it from coming apart and clamped 2×2 angle iron Cody had lying around the garage to keep it from bowing while everything dried. We let it sit overnight and moved onto the sink cutout in the morning

Step 4: Cutting out the sink

This is a picture of Cody totally screwing up the cut for the under mount sink with no safety glasses and a pen in his hand. According to Cody this photo should be deleted. Once he messed up the cut for the undermont sink there was no going back. Our options were to buy a new counter top and try again or get a top month sink. We opted for the second choice. If you have your heart set on an undermont sink I suggest you hire a professional to cut out the sink.

Since the second sink is a top mount, it is pretty straight forward, use the template that comes with the sink and cut the hole where you want it. We strategically chose to put the sink smack in the middle of the seam to mask the seam as much as possible

We then used wood filler to fill what was left of the seam, let dry, and sanded it smooth.

Step 5: Staining Butcher block

AS soon as we had decided on butcher block we knew we wanted to stain it. Honestly, Cody has wanted dark wood counter tops since he saw Emily’s on Revenge, but we were also inspired by this one and this one. I let Cody choose the stain color and he choose Minwax’s Dark Walnut after seeing some other blogger’s success with it.

To apply the stain I used two old socks. You can either apply stain with a rag or with a brush but I find that a rag gives me more control with no drips and it doesn’t ruin a brush. Because stain will, well stain, you want to wear latex gloves to protect your hands. I used one sock to apply the stain and after about 3-5 minutes I used the other sock to wipe off and buff the surface. You want to make sure to always apply the stain in the direction of the grain and never allow any stain to accumulate and dry on the surface.

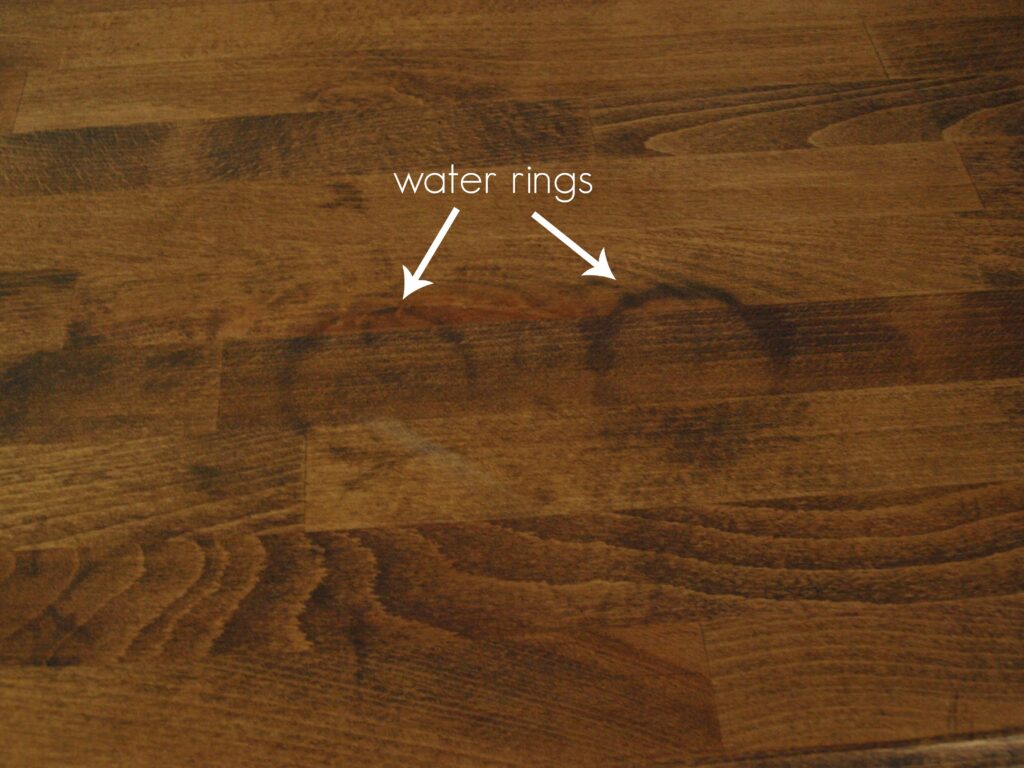

I did run into one little snag while staining. See we were so happy about having counters for a while that we sort of used them before we stained them. I made sure to clean them up before staining but while staining some water stains started magically appearing where the glasses had once been. I started to freak out, but luckily a light sanding with the electric sander took them right out. Lesson: don’t be tempted to use your countertops until after they are sealed.

I applied two coats of stain total. I did one in the morning and one in the evening. You can see a wonderful difference below. Look how much richer and warmer the stain wood is. I was actually a little worried that the stain was too dark, but we had already been forewarned that the sealer would lighten it a shade, so I wasn’t too worried.

Step 6: Sealing Butcher block

Sealing the countertops is by far the longest part of this process. If you stained your butcher block you need to wait 3 days before applying the sealer. After reading all the blogs about sealing countertops the overwhelming recommendation was to use Waterlox. As in no one actually recommended anything else. You can order it online but we were able to find it at a local woodworking store. It comes in original (semi-gloss), satin, or high gloss. No matter what finish you choose you have to do the first 4 coats with the original. Cody was really leaning towards the high gloss, but in the end we opted for 5 coats of the Original with the option to add a high gloss top coat down the road if we want to. The Original goes on in a pretty glossy finish that will fade down to semi-gloss in the first 3 month as it continues to cure. We needed 2 quarts to cover 5 coats on our counters.

Besides the sealer you will also need: A High Quality Natural Bristle brush mineral spirits: I highly recommend this odorless Eco-friendly brand sanding block tack cloth latex gloves Make sure to sand the counters with the sanding block than remove any debris with a tack cloth before applying the sealer. I applied the waterlox using a high quality natural bristle brush in thick coats. We found that thick coats actually created a smoother finish. In between coats rinse the brush with mineral spirits to keep it from gooping up. We applied 5 coats total, 24 hours apart than waited 72 hours before placing anything on the counters. The hardest part of this entire process was not using the counter tops for over a week!Waterlox claims that you do not need to sand after the last coat but we found that the counters were a little rough, so we gave it a light sanding with a fine grit sanding block which really brought out the finish even more.

Results

This was a really long process but look how beautiful the counters turned out in the end! It’s hard to believe that these gorgeous counter tops were the cheapest option we had!

By far the best decision we made was routing the edges of the counters. I feel like that is what really gives them a custom high end look.